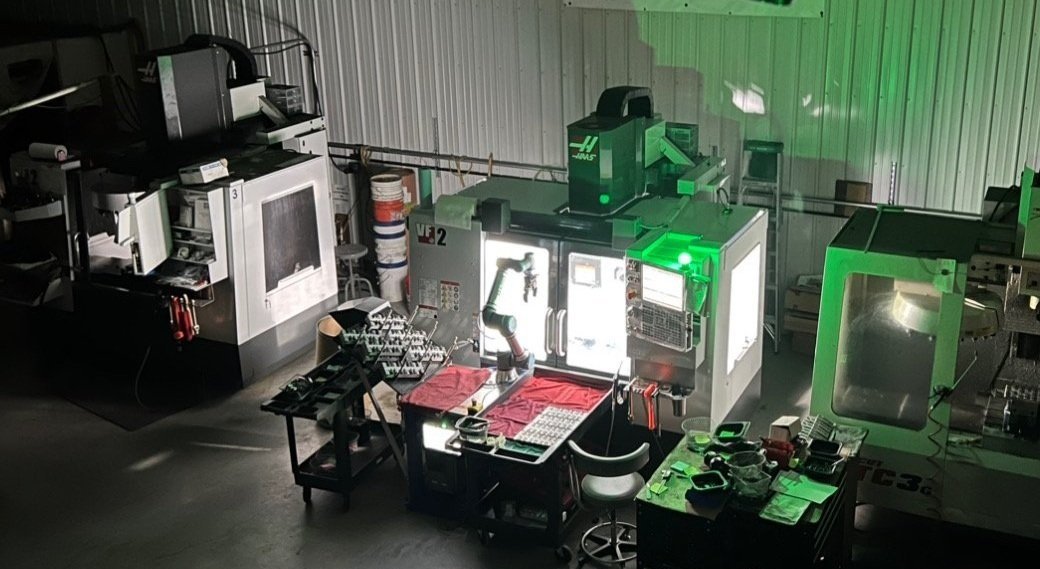

Employees Are Too Valuable

To Be Loading Machines.

Machine Shop Automation works best when it allows them to do higher-value tasks while giving you the confidence that automation can – and will – meet your needs.

Step 1: Book A Discovery

Step 2: Execute a Strategy

Step 3: Enjoy Free Time

Future-Proof

Your Machine Shop

Get Your Free-time Back with

Flexible, Integrated Automation

Keep Your Employees. Happy.

When you let employees do valuable work,

you attract - and retain – higher talent.

Get Your Time Back

Spend more time doing continuous improvement, and leave time for what you love.

Be More Competitive

With lower costs, more throughput and reliable employees, you will be a step ahead of your competition.

Hear What People Are Saying

Universal Robots

Top Integrator

2022 & 2023

“The quote was spot on, it was on time, delivery and installation was smooth and successful, programming for our application was perfect… Since installation, we have had ZERO issues with our system. Zero service calls or customer support needs… She runs perfectly with out a hitch.”

Step 1: Book A Discovery

Enjoy a meeting where we listen to your needs to understand where automation could help you the most

Step 2: Execute a Strategy

Execute a plan that is tailored to your needs so you can get your free time back

Step 3: Enjoy Free Time

Whether it is that project you've been meaning to get to or something fun outside of work.

You now have the time!

When you go Lights Out,

You Go Future Proof

You realized you need to automate and then wondered… Will it meet my needs? It’s time to implement a Lights Out solution you know will last.

We know how chaotic it is to run a machine shop and how hard it is to find employees

We have jumped the hurdles of automation and we can guide you through it

WHAT WILL GOING LIGHTS OUT MEAN FOR YOUR SHOP?

Increased Throughput

Our customers found they get more parts made per week with direct part loading than any other method.

Lower Inventory

Shorten your lead times and stop ordering material way in advance.

Less Operating Expense

Labor is the most expensive piece of making parts. Stop having your star employees load parts into fixtures.