Education

The Internet of Things: Unlocking New Possibilities for Manufacturing Automation

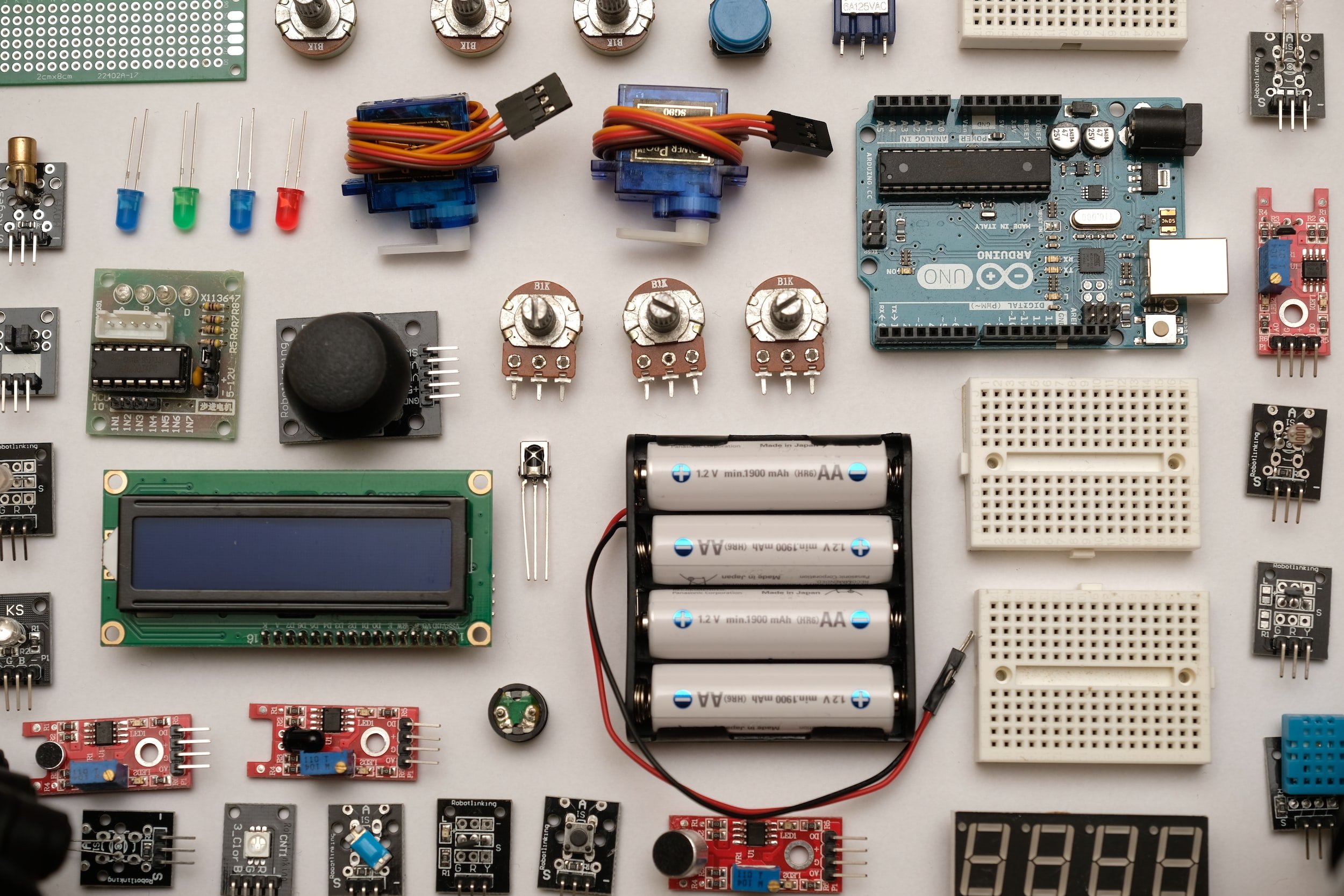

The Internet of Things (IoT) is revolutionizing industries across the globe, and manufacturing is no exception. By connecting devices, machines, and systems through the internet, IoT enables real-time data exchange, paving the way for more intelligent, efficient, and flexible production processes. This blog post will delve into the concept of IoT and discuss how it is transforming the world of manufacturing automation, including its impact on cobot machine tending.

Empowering Employees with Collaborative Automation

The manufacturing landscape is rapidly evolving, and small to medium-sized manufacturers are facing unique challenges in this ever-changing environment. One major issue is the struggle to find and retain skilled employees, compounded by the increasing reliance on automation. At Lights Out Mfg, we recognize these challenges and are dedicated to helping both employers and employees embrace automation without fear or resistance, using collaborative robots from Universal Robots.

Industry 4.0 and Collaborative Robots: Unlocking Potential for Small to Medium Manufacturers

Industry 4.0 is revolutionizing the world of manufacturing. It represents a new era in industrial automation and technology, characterized by the integration of digital systems, automation, and advanced data analytics. Among the many cutting-edge technologies at the heart of Industry 4.0, collaborative robots, or "cobots," have emerged as a powerful tool for small to medium-sized manufacturers. In this blog post, we will explore what Industry 4.0 is and how cobots can help these manufacturers automate their CNC mills and lathes, leading to improved efficiency, cost savings, and competitiveness.

The Future of Manufacturing: How Automation is Transforming the Industry

The manufacturing landscape is continuously evolving, with technological advancements driving significant changes across the sector. One of the most impactful shifts is the rise of automation in production processes, enabling increased efficiency, cost-effectiveness, and competitiveness. This article explores the future of manufacturing and how automation, particularly in the realm of cobot machine tending, is revolutionizing the industry.

Benefits of Cobot Machine Tending: Boosting Efficiency and ROI in CNC Operations

Cobot machine tending is quickly becoming a popular choice among manufacturers looking to improve their CNC milling and lathe operations. By automating the loading and unloading of workpieces, collaborative robots (cobots) are transforming the way small to mid-size manufacturers approach production. In this blog post, we will discuss the key benefits of implementing cobot machine tending, and how it can significantly boost efficiency and return on investment (ROI) in CNC operations.

Lean Robotics: Streamlining Robotic Automation in Your Factory

Lean Robotics, a concept introduced by Samuel Bouchard, CEO of Robotiq, is a methodology designed to simplify and optimize the integration of robots in manufacturing environments. Drawing on the principles of lean manufacturing, Lean Robotics focuses on minimizing waste and maximizing efficiency in robotic automation. Here, we present a condensed overview of the main ideas and steps involved in implementing Lean Robotics in your factory.

Top Considerations When Implementing CNC Automation Solutions

As the manufacturing landscape continues to evolve, small to mid-size manufacturers are increasingly turning to automation solutions to optimize their CNC milling and lathe operations. However, integrating automation into existing production processes can be challenging, especially for companies with limited experience in this area. To help ensure a smooth transition and maximize the benefits of automation, here are some top considerations when implementing CNC automation solutions.

Toolcraft's Success Story: UR5e Cobot Boosts Production and Reduces Costs in Medical Device Manufacturing with Lights Out Mfg's Integration

Toolcraft, a small machine shop based in Seattle, Washington, manufactures high-precision parts for aerospace, medical, and defense industries. Faced with labor shortages and the need to increase production, the company turned to Lights Out Mfg to integrate Universal Robots' UR5e cobot into their operations. By automating a complex three-operation machine tending task, Toolcraft experienced a 43% increase in throughput and a 23% reduction in production costs.

Understanding Six Sigma: A Guide to Improving Business Processes

Six Sigma is a widely-adopted methodology for process improvement in various industries. Developed by Motorola in the 1980s, it is a data-driven, statistical approach designed to identify and eliminate defects in business processes. Six Sigma seeks to reduce variability, enhance efficiency, and improve customer satisfaction. In this blog post, we'll provide an overview of Six Sigma, its principles, and how it can benefit businesses.

Exploring the Future of Cobots: 5 Key Trends in Collaborative Robotics

Collaborative robots, or cobots, have revolutionized the world of automation, offering versatile and easy-to-implement solutions across various industries. As cobots continue to evolve, they will play an increasingly important role in manufacturing and beyond. In this blog post, we will explore five key trends shaping the future of cobots and their potential impact on businesses.

Addressing Common Concerns About Automation and Job Displacement

The rise of automation has brought significant advancements in productivity and efficiency for industries worldwide. However, it has also raised concerns about the potential impact on job displacement and the future of work. In this blog post, we will address common concerns related to automation and job displacement and explore how businesses can successfully implement automation while supporting their workforce.